ACP Composites, Inc.

Custom composite manufacturing solutions for the most demanding applications

CNC machining, finishing, ply cutting, assembly, and more value-added services

ISO 9001, AS9100-certified, and ITAR-registered composite manufacturer

Custom composite sandwich panels, laminates, tubes, rods, and formed structures

Browse our in-stock collection of sandwich panels, laminates, tubes, and rods

Since 1985, ACP Composites has specialized in designing and manufacturing custom composite structures, plates, flat panels, and other customized products that change the way the world approaches complex operating environments. By following the basic principle of “customer-centric innovation,” ACP Composites has remained focused on developing products that meet the specialty needs of customers in high-performance and critical industries. With a penchant for high-quality composites, affordable options, and decades of successful customer partnerships under its belt, ACP is driven to become the leading custom composite manufacturer for clients in the aerospace, recreational, medical, and industrial sectors.

ACP Composites is proud to offer the most comprehensive collection of composite fabrication, molding, and curing equipment under one roof at our California-based facility. Our autoclaves, ovens, and presses are all industry-leading pieces of equipment capable of creating the most advanced composite products available on the market. Our ISO 9001 and AS9100-certified composite manufacturing processes guarantee that all final products meet customer design specifications exactly and maintain consistent quality standards throughout the production run.

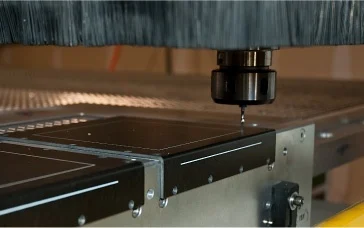

In addition to manufacturing custom composites, ACP offers a variety of additional value-added services to help streamline production, keep projects on-time, and provide competitive pricing. From sourcing initial materials to CNC machining and finishing your composite parts, to light assembly work and ply cutting, ACP Composites is a one-stop shop giving clients access to pre and post-production services needed to bring composite projects to life. Contact us today to learn more about how we can help.

ACP Composites is an ISO 9001 and AS9100-certified composite manufacturing company specializing in the world’s most advanced composite materials and crafting customized solutions for demanding applications. Quality isn’t just what we deliver; it’s a driving force that guides our manufacturing process from start to finish. From First Article Inspection (FAI) Reports to document control systems and NIST-certified calibration practices, our composite manufacturing process delivers on our customers’ expectations for excellence while deploying innovative quality techniques across the company.

As an ISO 9001-certified custom composite manufacturer, ACP Composites is well-versed in delivering advanced composite solutions built to custom specifications. We produce high-strength and low-weight sandwich panels, laminates, composite tubes, and formed structures for demanding aerospace, industrial, medical, and other technical applications.

ACP Composites produces lightweight, high-strength sandwich panels by bonding composite prepreg to honeycomb or foam cores. Available in AL-X Aluminum, carbon fiber, and fiberglass, these panels deliver exceptional stiffness-to-weight performance for aerospace and automotive applications.

ACP Composites manufactures custom laminates using epoxy resin systems and advanced fiber reinforcements for strength, stiffness, and temperature resistance. Options include carbon fiber, fiberglass, structural foam, and NOMEX honeycomb, tailored to precise performance requirements across demanding industries.

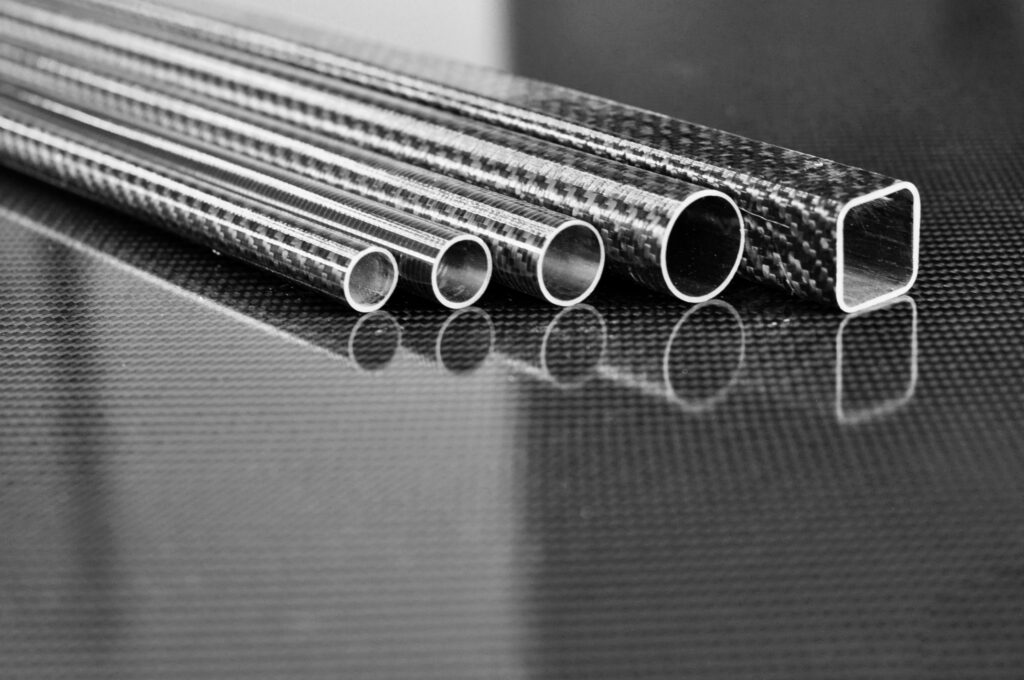

ACP Composites manufactures lightweight, high-strength composite tubes and rods using carbon fiber, fiberglass, and Kevlar. Produced via roll wrapping, pultrusion, or filament winding, these tubes maintain tight tolerances, outperform metals, and support machining, cutting, and finishing across diverse applications.

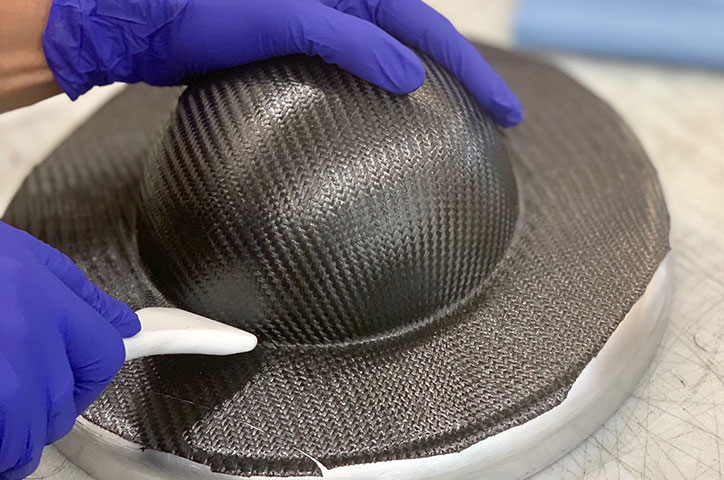

ACP Composites engineers complex composite shapes using carbon fiber, fiberglass, and Kevlar to meet specific structural needs. These custom geometries provide excellent strength-to-weight ratios, dimensional stability, and design flexibility for aerospace, robotics, industrial, and sporting goods applications.

ACP Composites manufactures custom composites for use in a diverse array of applications and industries that require incredible strength-to-weight ratios, consistent thermal performance, and resistance to extreme forces and corrosion.

Explore our state-of-the-art facility housing the most advanced manufacturing equipment.

Discover the machining and cutting capabilities of our 5 Axis CNC and other machining equipment.

See how our exclusive composite products and in-stock materials provide the solutions you need.

Discover the technology, ideas, and people driving uncrewed systems and autonomy forward.

By selecting pre-approve as the shipping option you agree to be billed separately for the actual cost of shipping after the order ships.